- Topics

- Campaigning

- Careers

- Colleges

- Community

- Education and training

- Environment

- Equality

- Federation

- General secretary message

- Government

- Health and safety

- History

- Industrial

- International

- Law

- Members at work

- Nautilus news

- Nautilus partnerships

- Netherlands

- Open days

- Opinion

- Organising

- Podcasts from Nautilus

- Sponsored content

- Switzerland

- Technology

- Ukraine

- United Kingdom

- Welfare

Hydrogen has been hailed for some time as a clean marine fuel that could help the shipping industry meet its carbon reduction targets. But it comes with significant challenges which we must all address together. Sarah Robinson reports

As the world attempts to reach its goal of 'net zero' greenhouse gas emissions by 2050, there has been a major push towards electrification. In the UK, for example, no new petrol and diesel cars can be sold from 2030 onwards, and all new cars and vans must be fully zero emission at the tailpipe from 2035. A ban on domestic gas boilers is also in the offing.

Of course, using electricity for vehicles and water heaters only truly cuts carbon emissions if the energy is generated from renewables such as wind and solar power, so electrification around the world is being accompanied by a phasing out of coal, oil and gas fired power stations.

Electrification can be applied to short journeys on sea as well as land, and a few battery-powered island ferries and tour boats are already in operation, but we will probably never see giant cargo or cruise ships with shore-charged batteries capable of crossing an ocean.

It's likely, instead, that a mixture of solutions will be needed to replace diesel and heavy fuel oil on these deepsea routes – including biofuels, ammonia and wind propulsion. But hydrogen stands out as arguably the cleanest fuel, as when it burns, it produces only water as a waste product.

Working towards hydrogen

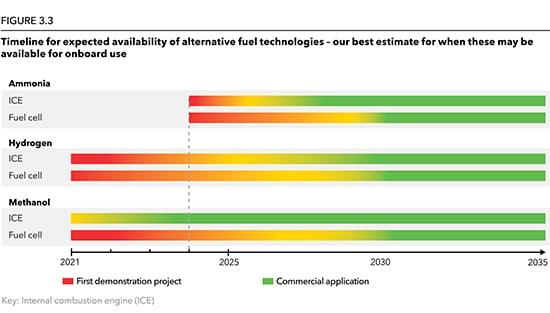

There are a great many pieces that need to be put in place before hydrogen can play a significant role as a marine fuel. The 2021 edition of the DNV Maritime Forecast 2050 shows that hydrogen is only at 'demonstration project' stage at the moment, with commercial adoption perhaps a possibility in the 2030s.

This contrasts with 'drop-in' alternative fuels such as bio-diesel or LNG, which are not as clean but are ready to use now, because the supply infrastructure is already here, and only moderate changes are needed to ships' engines.

With hydrogen, we are not quite starting at the very beginning, but there is a lot to do. The shipping industry must consider fuel storage and bunkering facilities, new ship designs and engine types, seafarer safety and training, and end-to-end CO2 abatement. Not to mention developing regulations that cover all of these.

Fuel storage and bunkering

Hydrogen is usually found as a gas, but needs to be compressed into a liquid and kept under high pressure and at a low temperature for use as a fuel. 'High pressure storage takes up a lot of space and can be expensive, because you need a compressor unit and a special tank made of high-strength steel,' says Odd Rune Malterud, assistant director and technical manager of the Norwegian Union of Marine Engineers.

'Hydrogen can also be highly explosive,' he points out, 'which you must consider when bunkering; there must be a very wide exclusion zone when the fuel is transferred. When we have planned it out as a marine fuel in Norway, it has to be bunkered in an empty fjord with no one living there.'

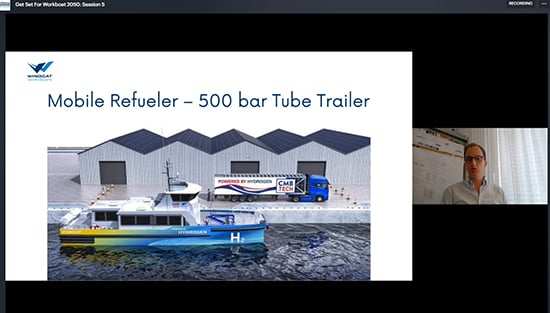

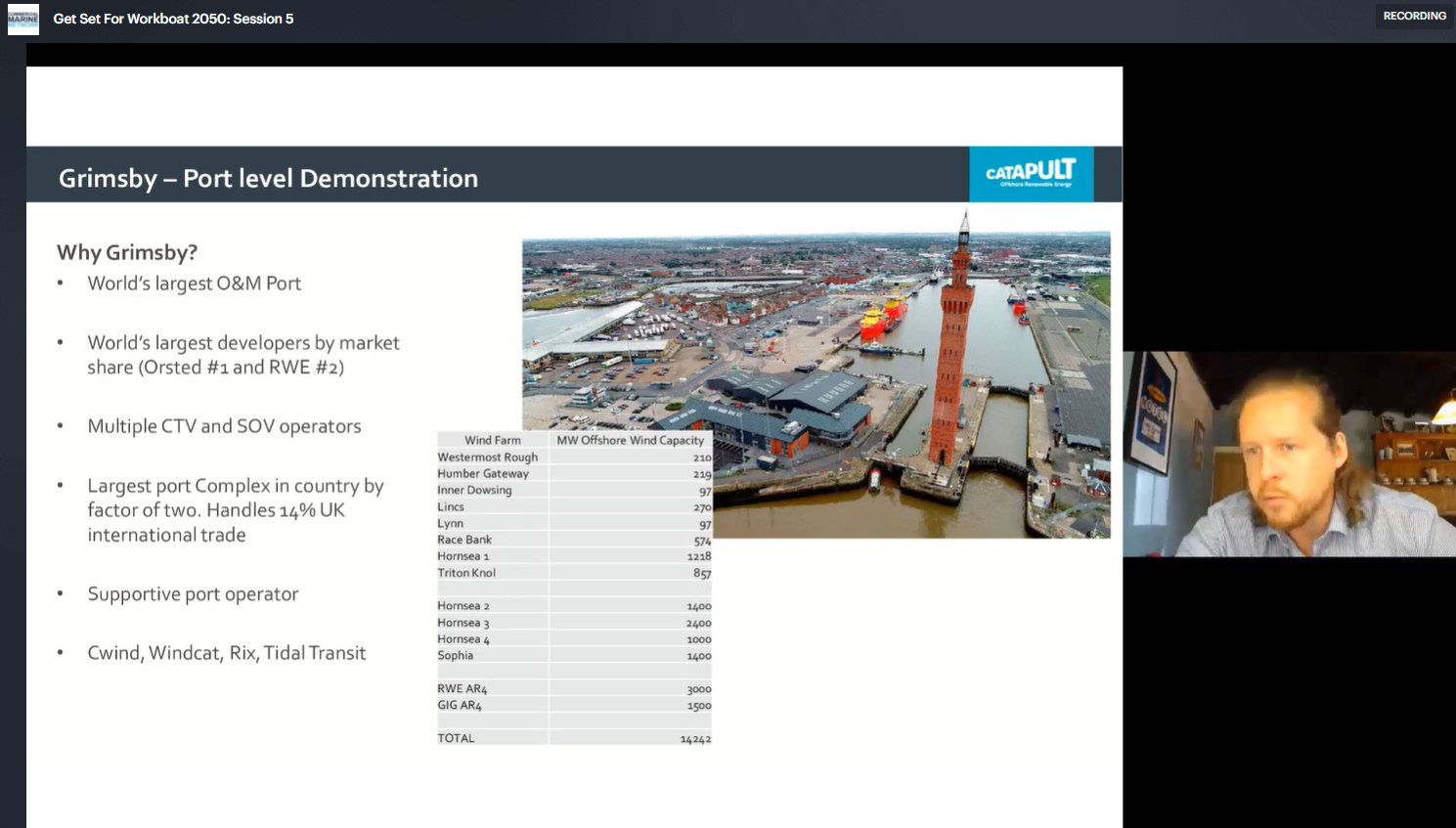

Nevertheless, plans are being put in place reporting on the feasibility of hydrogen bunkering facilities in ports such as Antwerp and Grimsby, as reported in the interesting Get Set for Workboat 2050 webinar series earlier this year. Options include 'tube trailers' carrying hydrogen in a series of pressurised canisters – trailers which could be driven to a suitable bunkering location.

Engine types and ship design

The use of hydrogen in an internal combustion engine (ICE) has been explored, particularly in combination with fossil fuels as an interim measure to reduce emissions on the path to net zero.

However, the eventual goal is to change the way a ship is powered by introducing an electric engine run off hydrogen fuel cells. Essentially a kind of battery, these fuel cells would generate electricity onboard through a chemical reaction within each cell – with water as the only waste product.

This would necessitate new ship designs, in large part because the fuel cell set-up would take up a lot of space. 'First you need hydrogen tanks to supply the fuel cells, with the accompanying compressor systems to keep them under pressure and cool,' says Mr Malterud. 'Then you have the fuel cell battery itself, and then the propulsion machinery.'

Another important consideration is the safe positioning of the fuel cells and hydrogen tanks. 'If something goes wrong, you will not get a slow-burning engineroom fire, you will get a massive explosion with no time to evacuate. The only solution is to put the hydrogen equipment on the open top deck with a thick steel blast wall protecting the wheelhouse.'

Regulations

Designing and building vessels suitable for hydrogen fuel cells is challenging but manageable, and the environmental imperative to do so is very strong. The DNV report argues that there will soon be a financial imperative, too, predicting: 'We can expect ships and shipping companies that perform poorly on emissions to be less attractive on the charter market'.

But to ensure all hydrogen-powered ships are built and operated at the necessary safety standards, we need a framework of national and international regulations, enforced by inspections. There is already the IGF Code – the International Code of Safety for Ships using Gases or other Low-flashpoint Fuels – but this initially focused on LNG and needs updating. Mr Malterud will be involved in these revisions at the International Maritime Organization (IMO) but is concerned at how much important regulatory work at the IMO has been delayed by the Covid-19 pandemic, potentially leading in the near future to dangerous unregulated experimentation in countries less watchful than his native Norway.

He also wants to see a shift in focus in all regulations relating to new marine technology, to put the safety and welfare of seafarers front and centre. 'We cannot accept developments that take care of the environment without taking care of our members, and that is why we go to the authorities and argue for safety and competence for the crew, as well as measures like blast walls on the deck and 200m evacuation zones during bunkering of hydrogen.'

Green credentials

There's one more issue to address before we go all-out for hydrogen as a marine fuel: it is not always as green as it seems.

The DNV report notes that 'current IMO regulations only address onboard tank-to-propeller CO2 emissions from fossil fuels'; in other words, the requirements for decarbonisation over the coming decades only apply to emissions from the ship itself. What about the way the hydrogen is produced and transported?

'In Norway, the hydrogen for the ships we have been trialling is made in France and transported here by diesel trucks!' says Mr Malterud. 'We need significant investment by governments in larger-scale local hydrogen production if this is going to work – we can't leave it to the market.'

There are also cleaner and dirtier ways of making the hydrogen itself. 'Grey hydrogen' has been produced for many years by splitting natural gas into hydrogen and carbon dioxide, releasing CO2 into the atmosphere from the splitting and from the fuel burned to power the process.

'Blue hydrogen' is like grey hydrogen, but with more efforts to use renewable electricity as a power source and a process in place to stop the CO2 from the splitting process from reaching the air using carbon capture.

'Green hydrogen' is the ideal, using renewable energy such as wind and solar to power electrolysis that splits water into hydrogen and oxygen.

What next?

Encouragingly, a move to significant production of green hydrogen in the UK is set out in a government policy document published in August 2021, which also acknowledges the importance of 'end to end' decarbonisation regulations that consider production, supply chain and decommissioning as well as vehicle emissions. Other countries, such as Norway, are also considering these issues, and Mr Malterud notes that 'good national strategies and regulations can provide a model for international regulations.'

Meanwhile, the DNV report has been very widely disseminated and is providing important data analyses for shipowners and maritime regulators. It also contains the strong message that the transition to cleaner fuels such as hydrogen – with all that entails – must now take place at a much faster rate if we are to meet global decarbonisation targets. Nautilus International, the Norwegian Union of Marine Engineers and all the other Nautilus Federation unions will be closely involved to make sure that seafarer safety and training is not left behind as the pace picks up.

- The 2021 edition of the DNV Maritime Forecast 2050 is available to download on request

- The UK Hydrogen Strategy can be found at www.gov.uk

Hydrogen can also be highly explosive, which you must consider when bunkering Odd Rune Malterud, Norwegian Union of Marine Engineers

What's the alternative?

In addition to hydrogen, we are likely to see a 'basket' of different marine fuels in the coming years – as remarked on by Magda Kopcynska of the European Commission at the launch of the 2021 edition of the DNV Maritime Forecast 2050. The time when one fuel fits all is coming to an end, she stressed.

With that in mind, what are the pros and cons of different fuels that seafarers are likely to encounter over the next thirty years?

Liquefied natural gas (LNG)

Pros: Reduces nitrigen oxide (NOx) emissions by up to 80% and almost eliminates sulphur oxide (SOx) particles. Non-toxic and non-corrosive. LNG spills cause little marine environmental damage unless ignited before evaporation can occur. Safer than current liquid fuels.

Cons: Still produces emissions (though could be useful in the transition). Converts to highly flammable gas when in contact with air, carrying risk risks of fire, explosions, etc. Engine room, motor rooms and cargo compressor rooms are most likely points.

Timeline: Environmental benefits (and fuel costs) have driven uptake of LNG in recent years. LNG is already available in most major shipping hubs.

Batteries

Pros: Zero emissions (if power is produced through green technology). Quieter for crew members. Scent free. Less maintenance. Practical for vessels that dock often and therefore have time to recharge, such as ferries, or as part of a hybrid system.

Cons: Still not efficient – cannot store enough energy for their size and weight. Production can cause environmental damage. Emissions from power produced using fossil fuels.

Timeline: Some inland vessels which can use smaller batteries already exist, with plans for larger vessels (e.g. cruise ships). However, there is no sign that batteries will be a practical solution for large cargo vessels in the near future.

Methanol

Pros: No NOx and SOx emissions. Particulate emissions very low. Compatible with most engine types. Currently cheaper than hydrogen and ammonia. Liquid, therefore easier to handle than some alternatives.

Cons: Not emissions free (but could be useful in the transition). Toxic – it must be safely handled onboard the ship and during bunkering, though it is less toxic than heavy fuel oil or diesel.

Timeline: Methanol fuelled ships are already being used and built. Existing infrastructure means that methanol is available in more than 100 ports globally, but production would need to increase to meet extra demand from shipping. Drewry expects half of all vessels ordered after 2025 to have dual-fuel engines, with a large percentage using methanol as a marine fuel.

Nuclear fission

Pros: Small modular nuclear fission reactors produce zero emissions. Vessels are 50% faster than oil-fired ships of the same size. Highly reliable, with low fuel use. United States nuclear naval vessels have an excellent safety record – nuclear sailors have lower cancer death rates than the age-matched group in the general population.

Cons: High cost to produce.

Fission reactors produce contaminated waste and long-term, safe storage options are rare.

Timeline: Small nuclear reactors are already in use on submarines and surface vessels such as the aircraft carrier USS Dwight D. Eisenhower. Also used successfully aboard Soviet icebreakers. However, societal opinion of nuclear is poor, which could slow civilian uptake, and construction is expensive. Other nuclear options, including fusion and thermal power from spent fuel rods, are being explored.

Ammonia

Pros: Zero CO2 emissions when combusted. Green ammonia (from renewable electricity, water and air) causes no CO2 emissions during production either. Easy to store and transport. Can be kept in liquid form under atmospheric pressure, and at a higher temperature than hydrogen. High energy density, so storage aboard is feasible.

Cons: Most ammonia is currently produced from natural gas, and is therefore not zero carbon. Requires mix with pilot fuel for combustion. Green ammonia will initially be more expensive. Highly toxic in comparison with current fuel oils – even small volumes in the air can be fatal. Highly corrosive, especially when mixed with water. Different requirements compared with current fuels could require redesigns and new training/safety procedures.

Timeline: Dual fuel ammonia engines are being developed. Major companies such as Maersk are exploring the use of ammonia and pilot projects are in development. However, supply, infrastructure and safety related challenges must be solved. Large-scale investment in green ammonia production may be needed to reduce costs.

Tags